It has certainly happened to you that you find a lot of terms like “sapwood” or “softwood” when reading about wood or visiting a carpentry shop but you have no idea what they mean.

Don’t worry, through this blog you’ll learn the basic technical concepts so that you can choose and work with the wood that best suits your needs.

What is wood?

The short answer would be that wood is the material composing the trunk, the branches, and the roots of trees. It is the assembly of many cells of various shapes and sizes.

Therefore, it has no uniform structure and its function is to fulfill three tasks in the tree:

- It conducts the sap, i.e. the water and dissolved nutrients.

- It transforms and stores reserve substances, and at the same time, it is the material that supports, gives structure and resistance to the tree.

- It is in charge of supporting the structure of the tree.

In addition, wood is the part of the tree that grows year after year through a system of concentric and circular layers called rings or growth rings.

Characteristics of wood

In addition to the above, wood is:

- Resistant to tensile and compressive forces.

- Insulating against cold and heat.

- A material that doesn’t accumulate static electricity since it has low electrical conductivity.

- Sustainable, i.e., it can be obtained indefinitely with proper care of the forest and responsible logging.

- Reusable and biodegradable, in short, it does not pollute.

- Wood is what distinguishes a tree from an herbaceous plant: any plant that produces no wood and whose tissues are tender or soft.

Wood composition

Wood is mainly made up of the following components.

Cellulose

Cellulose is the substance that forms the cell walls of plants. It is arranged as fibers and additionally provides structural support to the tree. It also gives protection to the tree as it is very resistant to chemical agents, and at the same time, it is practically insoluble.

Cellulose represents 50% of wood.

Lignin

Lignin is the component that binds cellulose fibers together like glue, providing rigidity and hardness. It represents 30% of wood.

Various components

In addition, wood is composed, to a lesser extent, of other substances such as starch, tannin, colorants, camphor, and oils. These together account for the remaining 20% of wood.

Resin

Resin is not a tree’s exclusive component but a common characteristic in many plant species; it is a brown or yellow, liquid and sticky substance secreted to protect the plant from injuries such as wounds and cuts.

Botanic and commercial classification of wood

We can find that all commercial timber tree species are organized into two large groups: conifers and hardwoods.

Coniferous woods

Conifers or softwoods are tree species characterized by their easy-to-work wood. They are light or not so dense, so they are easier to transport and, consequently, that makes them more economical. However, they have less resistance and a shorter lifespan compared to hardwoods.

Now that you know this, keep in mind that the terms soft and/or mild are not directly related to the actual hardness of the wood, as some softwood species, such as Pine, have a harder and denser wood than Balso, a hardwood species.

In the following table, you’ll find the most important features of softwoods.

| Location | Tree species typical of temperate climate zones are present in both the northern and southern hemispheres. |

| Leave type | Evergreen. These species never drop their leaves. |

| Most used trees | Fir trees.Pine trees.Cedars. Spruce trees. Cypress. |

| Growth rate | Trees with rapid growth. |

| Difficulty to work | They are easy to work with, although they produce resin and splinter easily. |

| Applications | In most cases, softwoods are used in jobs where great resistance is not required, such as the manufacture of Furniture of all types. Musical instruments such as electric guitars. Handicrafts. Boxes. Packaging.Paper pulp. |

| General Features | Softwoods usually have less veining and density than hardwoods. They have light tones, so they need treatments such as staining and/or varnishing. |

Hardwoods

Hardwoods, also known as deciduous wood, broadleaf wood, porous wood, or broadleaf wood are tree species whose timbers are known for their high strength and quality.

Now, using the chart below, compare the characteristics of hardwoods with softwoods.

| Location | Hardwoods are tree species found throughout the world. A distinction is usually made between temperate hardwoods and tropical hardwoods, depending on their geographic location. |

| Leave type | Deciduous leaves. That is, their leaves fall off in winter. |

| Most used trees | OakChestnutWalnutElmMahogany. |

| Growth rate | Slow-growing trees. |

| Difficulty to work | These woods produce little resin and rarely have knots, therefore, they are higher quality and more expensive woods, although they are more difficult to work with. |

| Applications | These species are usually used in works of o Joinery (for more resistant furniture).o Musical instruments.o Boatbuilding.o Shipbuilding. o Construction in general |

| General Features | Finally, in contrast to softwoods, hardwoods have a greater variety of colors, with a richer grain and a more complex finish. |

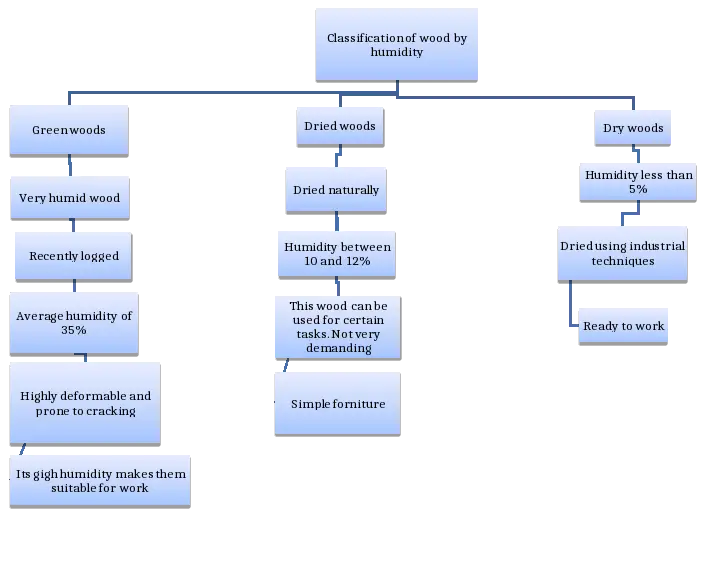

Classification of wood by moisture percentage

This is an important measurement because you will often hear the term “green woods”. It refers to the degree of humidity that the wood has during processing.

We explain it below.

Wood structure

In order to describe this topic, it is necessary to see a cross-section of the tree trunk so as to distinguish the following parts, which you have to know since they’ll serve as an indicator of the type of wood.

Next, we’ll make a description of each one of the parts.

Bark

It is the outermost layer of the trunk whose function is to protect the tree from environmental factors (rain, sun, dust, etc.) and aggressive agents such as insects, fungi, and bacteria.

Liber or phloem

This is the inner bark. It is after the bark and is responsible for covering the sapwood and conducting the sap (water and nutrients) to all parts of the tree.

Cambium

It is a thin, transparent layer attached to the sapwood and its function is to build the new wood.

Sapwood or wood

This is the newly formed wood. It can sometimes be recognized because it has a lighter color than the heartwood (although not always, since there are cases in which they are indistinguishable to the naked eye). Also, sapwood contains more water and nutrients but it is less resistant and, with time, it becomes a harder and more consistent wood.

Better said, you can use the sapwood in woodwork that is not very demanding from a mechanical and aesthetic point of view, perhaps for a simple chair or a table.

Heartwood

This is the structural support of the tree and, in fact, the most exploitable and useful part of the trunk, as it is the wood itself: that is, wood extracted for commercial purposes. This wood is dry, and hard, with greater consistency and a darker color when compared to sapwood.

Pith

This is the central part of the trunk and is characterized by low strength, resulting in poor-quality wood, which is generally discarded.

Growth rings

Lastly, we have the growth rings. Simply put, when a tree grows in a seasonal site, these define periods of active wood growth throughout the year. In these cases, the diameter of the tree trunk usually grows during the spring, summer, and sometimes even in the fall.

During the spring, a tissue of thin-walled cells called the lumen, early wood or springwood, originates. Whereas in the summer and fall a thick-walled tissue called Latewood or Summerwood is formed.

So, by having a tree trunk cut crosswise, we see that the succession between Springwood and Summerwood gives the appearance of concentric circles. They are called growth rings.

In contrast, in areas without seasons and, therefore, where there is a definite period of growth throughout the year, it is possible to speak of annual growth rings. In these particular cases, we can use them as a tool for calculating the age of the trees.

Finally, we find that in tropical zones the rings do not form in a defined manner unless the trees grow in places where there are 2 well-defined seasons of winter in the form of rain and summer in the form of droughts during the year.

Properties of wood

The general properties of wood are classified as physical, mechanical, and organoleptic; you need to take them into account when choosing your wood.

Physical properties of wood

These properties tell us about the measurable characteristics of wood.

Density

Let’s start with density, defined as the ratio of mass and volume in an object.

Also remember that even trees of the same species can vary in density, as this property varies according to factors such as the availability of nutrients in the soil and solar radiation, among others.

Finally, it is very important to follow the international wood density figures that we will see below as a guide so that we know what kind of wood we are looking at.

| Density (kg/m3) | Category |

| 400-499 | Light |

| 500-700 | Semi-heavy |

| 750-950 | Heavy |

| More than 950 | Very heavy |

*If the density of the wood exceeds 1000 kg/m3, it will not float.

Conductivity

Thermal conductivity is the intrinsic ability of materials to conduct heat through their surface and is measured in watts per meter per degree Kelvin (V/mk).

In terms of wood, what interests us is that it is a relatively low property due to the porosity of the material (empty spaces that exist between the molecules of the wood). So we have that:

- The higher the wood density, the higher its thermal conductivity.

- The more humid the wood is, the more conductive it will be.

- The lower the wood’s temperature, the higher its resistance will usually be.

Hygroscopy

Hygroscopy is one of the most important qualities of wood as it can change its dimensions and even affect other properties such as its hardness.

Also, you can measure the humidity with special devices that provide standard measurements for more than 200 tree species, so you can compare the values when buying wood.

Natural durability of wood

Broadly speaking, we can say that the natural durability of wood is its ability to resist by itself, and without the help of varnishes or other treatments, the effects of being outdoors, and the attack of pests such as insects, fungi and bacteria, among others.

The measurement process is complex. It is done through tests done in a laboratory or by testing the wood outdoors and the measure is in relation to the years that the wood is able to maintain its properties while exposed to the action of aggressors such as fungi and water, among others.

Just keep in mind that, although wood may be said to be “durable” or “very durable”, it does not mean that it is invulnerable to pests or that it can withstand all types of environments and abuse.

Stability of wood

This property refers to the way wood interacts with temperature. That is, it is a measure of how much a piece of wood can shrink or expand relative to environmental temperature changes.

Coefficient of Volumetric Shrinkage

This is the shrinkage that wood experiences when the humidity percentage varies by 1%. In simpler terms, this coefficient allows us to know to what extent the wood’s volume will change as humidity increases or decreases.

Therefore, the lower the coefficient of volumetric shrinkage, the more stable or less nervous the wood will be. That is, its volume remains more or less constant when faced with variations in humidity in the environment.

Do you remember wood hygroscope? – It is closely related to the coefficient of volumetric shrinkage.

| Volumetric shrinkage coefficient | Stability level |

| 0,15- 0,40 | Very stable wood (not very nervous) |

| 0,35 – 049 | Stable wood (somewhat nervous) |

| 0,40 -0,55 | Somewhat stable wood (moderately nervous) |

| 0,55 – 0,75 | Unstable Wood (nervous) |

| 0,75 – 1 | very unstable wood (very nervous) |

Impregnability

Wood impregnability is the quality of wood to introduce and move liquids in its interior.

This property varies according to the species, type, and part of the wood.

For example, hardwoods have lower impregnability than softwoods, while sapwood is more impregnable than heartwood in all species. For example, the impregnability of oak (which is a hardwood) will certainly be lower than that of pine (which is a conifer).

To measure the impregnability, the wood is introduced in a machine in which a substance is a pressure applied to it, and the area that this product was able to penetrate in the wood after 3 to 4 hours is measured.

According to EN 320-2, the impregnability of wood is classified as follows:

| Category | Description |

| Impregnable. | Very easy to impregnate wood.If the wood is sawn, it can be fully impregnated with pressure treatment without difficulty.. |

| Moderately impregnable. | Easy to impregnate wood.Normally it is not possible to achieve complete impregnation, but after 2 to 3 hours of pressure treatment a penetration of more than 6 mm can be achieved in conifers.In hardwoods impregnation can be achieved in a large proportion of the vessels. |

| Little impregnable. | Difficult to impregnate.After 3 to 4 hours of treatment under pressure, only penetrations of 3 to 6 mm are achieved. |

| Not impregnable. | Virtually impossible to impregnate. After 3 to 4 hours of treatment under pressure, only small amounts of product are absorbed. Minimal longitudinal and lateral penetrations. |

Porosity

The wood surface is not compact as a whole; rather it is composed of very small cells arranged uniformly.

If you are going to work with wood, you should always take this property into account since it is necessary to “close or “plug” those pores so that the paint adheres well. The same happens with the varnish or oils that must be added to the wood pieces.

Mechanical properties of wood

The mechanical properties of wood are its characteristics regarding its capacity to transmit and resist forces or deformations when a determined force is applied to it.

Hardness

It refers to the resistance of wood as a material and is directly related to its density, and inversely related to humidity. This means that:

- The greater the density, the greater the hardness of the wood.

- The higher the humidity of wood, the lower its hardness.

We understand wood hardness as the opposition of the material to scratching and nail penetration, screws, the passage of the planer, and the action of the saw or chisel.

There are three methods for measuring hardness in wood: Brinell, Janka and Monnin, which is the most widely used and the one we will talk about.

The Monnin test is a laboratory technique in which a load of 100 kilopascals (Kp) per cm of specimen width is applied to a piece of wood through a piece of steel 30 mm in diameter.

Subsequently, the footprint left by the steel piece in the wood is measured in order to associate this data with the penetration depth of the piece, and by means of mathematical calculations, a standard value to classify the wood is established.

Flexibility

Wood has good mechanical resistance to tensile, compression, torsion, and bending forces. It can also change shape, i.e., it can be bent or curved by applying heat and/or pressure or by manipulating its humidity levels.

Just keep in mind that wood will withstand these forces well if they are in the same direction as its fibers, otherwise it may break.

Flexibility is the ability of wood to change shape without its structure being damaged or breaking when a force is applied to it.

In addition, flexibility tests are done based on the thickness of each type of wood. These measurements are usually made in a laboratory because it takes professional tools to perform them if you want to obtain accurate data.

Finally, keep in mind that the more resistant wood is to bending, the better it will support the weight imposed on it. So, if you are looking for wood for structural construction, make sure it has good flexibility.

As a curious fact, wood is often treated with steam to increase its flexibility, which is especially useful in the manufacture of bent furniture.

Cleavage

Finally, cleavage is the ease with which the wood can be split in the direction of its fibers, i.e., it is easier to cut it following the path of the fibers and therefore, better quality wood will be obtained more easily.

Anisotropy

Anisotropy is a physical property that explains why properties such as the elasticity or strength of a material change depending on the direction in which they are measured or evaluated.

The fact that wood is an anisotropic material means that its mechanical properties vary according to the direction in which the fibers change at a given moment. That is, the mechanical properties of anisotropic materials are not symmetrical with respect to any plane or axis.

Therefore, it is important that you know the directions in which the wood fiber goes in relation to the axis of the tree.

Axial direction

If the fibers run in the same direction as the tree’s growth, we are dealing with an axial direction.

Radial direction

This is perpendicular (at a 90-degree angle) to the axial direction. This arrangement cuts the axis of the tree.

Tangential direction

It is parallel to the radial direction. Here the direction of the fiber appears to “cut” the growth rings.

So, now that you know what the directions of the wood fiber are, let’s have a look at some values that will help you especially if you work in wood construction.

Compressive strength parallel to the fiber

It is the force that wood exerts against an instrument when the instrument is operated parallel or tangential to the fiber.

Compressive strength perpendicular to the fiber

Here the force of the wood is exerted in a 90-degree direction in relation to the fiber or, in other words, radial to the fiber. This tells us how difficult or easy the planing will be. The higher this value, the more difficult it will be to plane that wood.

Static bending strength

This value tells us how much a piece of wood can resist loads that can bend, stress and compress it when the wood is still or at rest.

Modulus of elasticity

It is the ability of wood to resist deformation. Thus, the higher this value is, the more resistant or rigid wood is.

NOTE: We know this is a bit complex and abstract but you’ll understand it better when we talk about the fiber, because depending on the direction it has, working the wood will be easier or more difficult.

Remember also that these figures are only a guide obtained in laboratories and, although they can be useful to give you an idea of what kind of wood you are going to buy, it is not necessary that you learn the values by heart because as we have said before, each wood is different. In addition, there are many factors that influence the results when taking these measurements.

Organoleptic properties of wood

By this, we refer to the qualities of the wood that can be perceived with our senses. Now let’s see what they are.

Color

Let’s start with a characteristic that varies according to the type of wood, whether it is hard or soft. For example, we can see that the colors of hardwoods are strong and accentuated, while softwoods almost unequivocally have colors ranging from white to pale yellow.

Luster

The natural sheen of the wood.

Translucency

The ability of the material to let light pass through it. The more resin the wood has, the less translucent it will be, or conversely, the less resin, the more translucent it will be.

Smell

This quality helps us to identify the state of the wood since rotten wood will have an unpleasant odor. In addition, some woods are characterized by their odor, as is the case of cedar wood.

Grains

When looking at a piece of wood, we observe some lines or drawings along it that mark the direction in which the fibers of the tree grow. These patterns are known as grains.

Keep in mind that not all grains follow the same pattern and there are variations that can significantly influence the choice of wood for a given project since two boards of the same species can have a totally different appearance due to their grain and each tree has its own grain pattern, confirming that each piece of woodwork is a unique piece of work.

Knots

These are areas in the trunk in which the base of a branch has formed. Then, when the wood is cut, the knots appear in the form of broken lines above the grain.

To learn more about this feature, you can check out our blog on the process of obtaining wood.

Fiber

Do you remember wood anisotropy? Now you’ll understand what it’s for.

But first, let’s understand what wood fiber is.

Fiber is the grouping of wood cells arranged in the direction of the tree axis. Keep in mind that this direction can change and this explains why there are several types of fiber such as:

- Straight (Regular)

- Wavy (Irregular)

- Twisted (Irregular)

- Interlocked (Irregular)

In addition, you must consider the trunk growth because if the tree has grown normally, its cellular structure will be intact and aligned with its main axis and therefore the fiber will be straight and therefore easy to work with.

On the contrary, when the tree has grown irregularly, the direction of the fiber changes, and the fiber becomes oval, twisted or interlocked, depending on how abnormal the growth has been.

Working with such timbers will be more difficult. However, these woods are desirable because the vein pattern (grain design) is often more aesthetically appealing.

Likewise, it is important to know that the fibers determine how easy or difficult it will be to work the wood, because whatever the type of fiber is, it will always be better to work following its natural direction. For example:

Always brush the wood in the direction of its fiber, and this is easier in a straight fiber than in an interlocked one.

Note: If you work the wood in the natural direction of its fibers, it is said that you are working straight. This is the technique used when the grain is straight.

Conversely, if you work at a 90-degree angle from the natural direction of the fiber, you are working against it, and that is often how wood with uneven grain should be treated.

Grain

In conifers, the grain is the diameter of the tracheid, i.e., the structures through which the sap flows.

In hardwoods, these sap-conducting structures are not called tracheids, but vessels and the grain is the measure of their diameter.

You should know then that the grain is classified into three large groups.

Coarse or thick grain

It is said that the grain of wood is coarse when it is large and can be easily seen.

Medium or intermediate grain

When the grain is a little smaller than the large one but can still be seen without much difficulty, we are dealing with a medium or intermediate grain.

Fine grain

If the grain is very small and hardly visible to the naked eye, it is a fine grain.

Workability or technological properties of wood

To finish this blog, we’re going to talk about technological properties. They refer to the conditions in which the wood is found when it is to be worked. Thus, by workability, we refer to the following.

Sawing

This is the process by which the tree is logged or cut in the plantation or cultivation area.

But the sawing process can also take place in a carpentry workshop with planks or boards of wood and the aim is to cut them into smaller pieces.

Keep in mind that the denser and heavier wood is, the more difficult it will be for saws to cut it.

However, softwoods often produce a lot of resin and this substance can make it difficult for saws to cut well either.

Drying

This is the process by which any moisture present in the wood is removed.

It can be done naturally, that is to say, to leave the sawed wood (cut or felled) in a covered place, where it is not exposed to the sun or rain but to the passage of air because in this way the water present in the wood will evaporate.

On the other hand, there is industrial drying, in which the wood is placed in kilns to speed up the process.

So, instead of waiting weeks or months for the wood to dry naturally, you have the option of taking it to a sawmill to dry it for you in a matter of hours to a couple of days. But be prepared to spend a good amount of money because the process is not cheap.

Planing

This is the process by which imperfections on the surface of the wood are removed once it is dry.

This is done with a tool called a planer. In addition, it can be done with an industrial machine at the sawmill or in a carpentry or joinery shop using a hand tool.

The manual process is more time-consuming and difficult as it requires experience to do it well, but it provides a better finish and adds value to the piece of wood.

Gluing

Here “glues” are used to join the different pieces that are needed to form the desired structures.

Usually softwoods or coniferous are difficult to glue and, in addition, care must be taken with each type of wood, since there are some that do not resist well to acid pH glues and are damaged, and others do not work with alkaline glues.

Screwing or nailing

Here the drill will be your best friend, because it is very common that when you want to insert screws into the wood it cracks and that is where the pre-drilling comes in, that is, making fine holes in the wood with the drill so that the screws have a clear path and do not damage the wood as they enter.

This is done with hardwoods and even more so with softwoods.

Finishing

This step is very important because here it is sought that the wood has the final appearance that is desired. For this, products such as varnishes, stains, paints, and in general protective agents are used, ensuring that the quality of the wood increases.

As you have seen, wood is a unique and truly complex material. Now that you have read this, you are ready to understand the concepts necessary to choose the right wood for your projects.

Always remember that these values do not have to be memorized and are only a guide because each wood is a different world.

See you next time.